Protein alternates emerged as substitutes for conventional animal-based meat and dairy products with sources that were promoted as requiring less intensive production means. Industry focus has been on technological and industrial applications of alternative proteins, but it is the understanding of safety aspects that will be the key to long-term success. Failing to understand or ignoring the potential risks in producing or working with alternate proteins could inadvertently prove disastrous.

Plant-based proteins are the oldest and most widely used sources for animal protein replacement. But while they have the longest legacy of manufacture and use, plant-based proteins not only pose the risk of allergens, they also can be the source of anti-nutrients and thermally induced carcinogens.

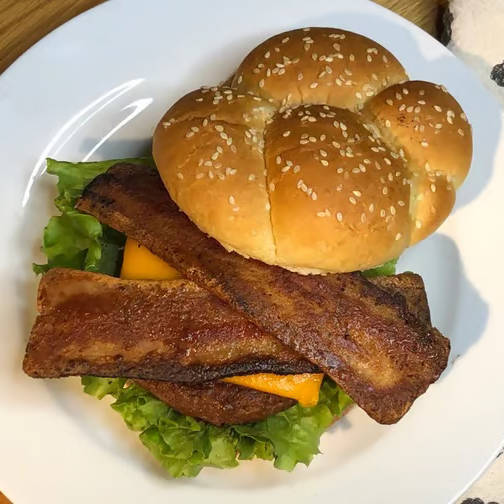

Mycoproteins are gaining greater use due to their ability to mimic textures of animal-based meats. Photo courtesy of Meati, Inc.

Fermented soybean cake (tofu and tempeh) or wheat (seitan), which have been consumed for centuries in Asian communities, and texturized vegetable proteins (TVP) from soy, wheat gluten, pea, and chickpea, used for decades as vegan alternates to conventional meat, did not emulate the sensorial properties of animal-based meats, nor were they truly intended to. These products were meat substitutes rather than analogs. To this end, they were not as manipulated as are the plant proteins on the market today.

Differences matter

The inherent differences between plant and animal proteins vary, depending on the plant source and how the protein is extracted and used. There are significant differences in physical and nutritional features, physiological properties, textural characteristics, and amino acid retention following extraction and thermal processing. Essential nutrients⏤typically vitamin B12, vitamin D, calcium, zinc, iron, and long-chain omega-3 fatty acids⏤often are missing from a diet that relies solely on plant proteins.

Shifting consumer perceptions of plant proteins pose challenges for today’s plant-based product developers. Photo courtesy of Getty Images / studiocasper

Plant-based meat and dairy analogs also can carry pathogenic bacteria originating from the raw ingredients. A critical issue for plant protein manufacturers is that, while extrusion inactivates some of these bacteria, it does not kill endospore-forming bacteria. Those that can survive extrusion processing include Clostridium spp. and Bacillus spp.

Another microbial risk is that the free amino-acid content and high pH of these proteins can favor recontamination by a range of pathogens, including Enterococcus spp. (especially Enterococcus faecium), Exigobacterium acetylicum, Acinetobacter spp., Staphylococcus spp., Lactobacillus sakei, and Carnobacterium divergens.

Worrisome inhibitions

Anti-nutrients, such as protease inhibitors, alpha-amylase inhibitors, lectins (especially phytohemagglutinins), polyphenols (particularly tannins), oxalates, goitrogens, phytoestrogens, and phytic acid, occur naturally in plants and are not destroyed during extraction and extrusion. Their negative physiological effects include altered gut function (via inactivation of digestive enzymes), reduced iron absorption, and endocrine disruption, among others.

Natural Toxins

Plants also produce metabolites designed to defend themselves against various threats and predators. Depending on the plant, these can include lectins, cyanogenic glycosides, glycoalkaloids, 4'-methoxypyridoxine, colchicine, and muscarine. It is therefore imperative for product developers to carefully select and process to avoid, remove, or deactivate such toxins.

Increased consumption of plants and reduced reliance on animal products is a winning idea with consumers as plant-based meal developers deliver higher flavor profiles with cleaner ingredients. Photo courtesy of CuliNEX, LLC

Such anti-nutritional compounds can even be harmful when ingested in high quantities or in isolation. It is important to ensure their inactivation. Even thorough heat application (170°C –180°C) only partially reduces the amount of trypsin inhibitor, phytic acid and tannins in products derived from corn, soybean concentrate, peas, and cassava. Therefore, testing for anti-nutrients is essential to setting the baseline of safety for plant-based proteins.

Beyond intolerance

Allergens associated with legumes can cause mild to life-threatening conditions by eliciting IgE-mediated immunological reactions. Most of these allergens belong to one of three protein families: storage proteins prolamins and cupins, pathogenesis-related proteins (Gly m 4 in soy), or prolifins (Gly m 3 in soy).

Thermal processing has not been shown conclusively to reduce their allergenicity. However, studies suggest high pressure, ultrasound, and pulsed light may further reduce allergen activity and could become the reason for selecting one supplier over another.

The configuration of proteins is the key to acceptance or rejection by the human immune system. Protein extraction methods that use pH and electrophoresis to separate and precipitate proteins from their native state have the potential to change their configuration and thereby, their safety for consumption. Protein suppliers can use differential scanning calorimetry to establish protein intactness, which reflects unchanged configuration and relative safety of their raw materials.

Cell Based Future

Cell-based meat (also known as in vitro, lab-grown, cultivated, or cultured meat) is derived by differentiating and proliferating embryonic or satellite stem cells in fetal bovine serum-based media. Associated risks include viruses or infectious prions in the growth media, as well as the safety of genetic engineering methods used in large-scale production.

The emulation of the structure and texture of complex animal-based meats requires understanding of the implications of the choice of stem cells. Multipotent stem cells—those which can only be differentiated into certain types of cells—such as adipocytes for adipogenesis, skeletal cells for myogenesis, microvascular networks for vascularization, and endothelial cells and extracellular matrix for fibrogenesis are favored over pluripotent cells which can be transformed into any type of cell. There also are embryonic stem cells, which can carry ethical issues.

The growth medium is a serum that provides essential nutrients, plus hormonal and differentiation factors along with growth factors. These currently are expensive and also pose safety and ethical concerns.

Yeast extracts and hydrolysates derived from food by-products such as chicken carcasses, fish bones, pork plasma, eggshell membrane, and egg white powder are emerging as viable substitutes, but with questionable aesthetics on food labels. Cyanobacterial hydrolysates such as spirulina are in the pipeline and undergoing safety investigations as viable nutrient sources for culturing cell-based meat.

Several gaps are evident in the current knowledge of cell-based safety. The most apparent issues stem from the animal serum, which must be free of viruses that affect cattle. Another potential hazard in animal serum is pathogenic and infectious prion (PrPSC -), a misfolded protein associated with transmissible encephalopathies, particularly due to cross-species and blood-related transmissions.

The production of cultured cells for human consumption is unprecedented and will continue to require a thorough assessment of the safety issues associated with scale production of meats using genetic engineering. On the plus side, cell-based meat is considered less susceptible to zoonotic diseases than conventional meat and as future technology brings down costs and simplifies production, it promises to sharply reduce the ecological impact of animal husbandry.

While thermal processing is key to reducing microbial activity and some anti-nutrients and allergens, it may also induce the formation of suspected carcinogens, such as polycyclic aromatic hydrocarbons, nitrosamines or heterocyclic aromatic amines. More studies are required to determine the potential safety risk of these chemicals in plant-based meat analogs. Still, testing to establish their absence or presence can go a long way to ensuring manufacturer and consumer trust in the industry.

One-cell wonders

Deriving proteins from single-cell sources is prized for its high sustainability factor. Nearly 60 years ago scientist and author Isaac Asimov predicted that in the future algae would be a primary food source that could eventually solve world hunger. His prediction might not be so far-fetched. Microalgae, fungi, and bacteria are finally being utilized in commercial amounts to craft highly bioavailable food proteins.

Soy has been the foremost plant protein source for millennia, and today’s product makers favor clean-label whole soy protein instead of solvent-extracted isolates. Photo courtesy of Karen Jones for Thrilling Foods, LLC

Several of the most biotechnologically relevant microalgae include green algae (Chlorella vulgaris), Haemotococcus pluvialis, Dunaliella salina, and spirulina (Arthrospira maxima or Arthrospira platensis). Spirulina, commonly categorized as a product of blue-green microalgae, is biologically classified as belonging to the phylum Cyanobacteria.

While known for their nutritional benefits, microalgae protein sources can also contain harmful substances, including toxic elements and toxins from contamination. Testing the growing substrate and the finished material helps establish spirulina purity and safety.

Product developers also should be mindful of potential allergic reactions to microalgae, especially to the beta chain of the C-phycocyanin protein. Used as both a nutritional and a natural blue food coloring, precautions in manufacturing spirulina include pre-harvest preventive measures and certificates of analysis. These also should include microbial load and characterization because the processing of microalgal biomass involves only minimal heat treatments.

Green Protein

The environmental impacts of alternative proteins can be attributed to the production of growth substrates or those that arise during cultivation. Life cycle analyses on commercial plant-based meat analogs suggest greater environmentally sustainable than conventional meats, as measured by energy use, CO2 emission, land use, water use, and eutrophication. The environmental impact of plant-based meats occurs during raw ingredient production, and the analyses must include the consequence and cost of not investing in increasing the efficiencies in alt-protein production technologies.

Alternative proteins from starch-fermenting fungi have been used to produce mycoprotein used in such commercial meat replacers as those made by Marlow Foods, Ltd.’s Quorn group. The main food safety hazard associated with mycoprotein is allergens. This includes not only the product itself but also the source of the refined glucose that sometimes is used in the growth medium. For this reason, mycoprotein makers are turning to non-allergenic alternatives.

Data are limited and adverse reactions point to mold allergies. Meati, Inc. relies on seasonings and whole mushroom roots to recreate the taste and texture of a range of meat and poultry products. A precautionary label mentions containing no mushroom but to avoid if sensitive to fungi.

Whole-plant ingredients, such as pork product analogs made from shredded jackfruit, make it easier to ensure safe proteins. Photo courtesy of Upton Naturals, Inc

The process

Proteins are usually extracted from plant materials to produce flours, concentrates, or isolates. Extraction and purification employ a range of methods that may include harsh chemicals such as acids, bases, and/or organic solvents. Green extraction methods use enzymes, individually or in combination, and advanced physical extraction methods can include ultrasound, pulsed electric field, microwaves, and high-pressure-assisted extraction.

These methods focus specifically on extraction and not on functionality optimization. A key to success with alternate proteins is establishing intactness and functionality while ensuring yield for commercial viability.

Regulatory Requirements

The food legislative framework is a necessary platform to ensure the safety of alternative proteins. Legislation related to genetic modification and GRAS is the current relevant regulatory framework to ensure alternative protein safety. In 2019, the FDA and USDA’s Food Safety and Inspection Services (USDA-FSIS) collaboration was updated to regulate cultured meat. FDA oversees cell collection, cell banks, cell growth and cell differentiation, while USDA-FSIS monitors post-harvest processes, including the production and labelling of the final cell-based food items. The Federal Meat Inspection Act and Poultry Product Inspection Act have also been proposed as supporting legislations.

Organic solvents (such as hexane) used during protein extraction can cause environmental and health concerns, particularly if the final product contains high residual amounts. Producers of pea and soy proteins could gain market trust by sharing how they test for residual solvents and what their analyses show.

Verifying the food safety of alternative proteins is clearly an important matter and is urgently needed to provide relevant food governing authorities with sufficient data to oversee that technological progress in this area is balanced with robust safety standards.

This article originally ran in Prepared Foods' May 2023 issue as "Alternative Proteins: Safety First!"